Step 1: Routine Maintenance

Routine Bridge Maintenance includes routine activities such as removal of

debris and grass, cleaning drainage spouts, etc and should be conducted in a

cyclic manner. DoR has approved norms for routine maintenance, [page 133]. No

priority list is generated using the BMS for routine maintenance. The budget

required for routine maintenance is allocated through Roads Board Nepal (RBN). The

budget required in each Division should be presented by the Division in the

Annual Road Maintenance Plan as per Norms. This is compiled in the Integrated

Annual Road Maintenance Plan by Maintenance Branch at national level at DoR

before forwarding to the RBN. Undertaking routine maintenance shall be carried

out as per the guidelines for routine maintenance of bridges, Refer

▬►Program

Appraisal Document BIMP Table 3.3: Maintenance Classification and Definitions,

Page 40, see an example of ARMP, Guidelines for Inspection and Maintenance

of Bridges Volume-1, Part -3, Guidelines for routine maintenance of bridges,

pages 121-134.

Program Appraisal Document BIMP Table 3.3: Maintenance Classification and Definitions, Page 40

Table 3.3: Maintenance Classification and Definitions

| Class |

Diagnostic |

Scope of Work |

| 1. Routine Maintenance |

No significant defect & no replacement or repair of any element of the bridge is required. The work involves routine activities to be conducted in a cyclic manner. RM is defined as the servicing of a bridge structure |

|

| 2. Minor Maintenance |

Damages detected are very minor and do not require any design input to carry out the treatment or rectify the defects. |

|

| 3. Major Maintenance |

|

|

| 4. Emergency Maintenance |

|

|

Guidelines for Inspection and Maintenance of Bridges Volume - 1, Part 3, Guidelines for routine maintenance of bridges, Pages 121-134

Guidelines for Routine Maintenance

1. INTRODUCTION

1.1 This guideline has been introduced in order to formalize the procedures for routine maintenance to ensure that vital maintenance functions are carried out regularly.

It sets out those operations, and their frequency, which are to be undertaken as Routine Maintenance.

Many of the tasks listed in this guidelines are fairly minor in themselves, but failure to carry them out may lead to deterioration of the structure, and the need for more serious repair operations in the future.

1.2 The items of routine maintenance work described in the guideline should be regarded as those which relate to bridge servicing rather than bridge repair and the work will be undertaken regularly at pre-determined intervals : 2 to 3 times a year.

1.3 Routine maintenance does not cover the renewal of structural elements or components which have become unserviceable because of general wear and tear or have deteriorated for other reasons. Such work should be identified during the regular inspection process, and should be included in a planned structural maintenance programme.

1.4 An interim norms for the Routine Maintenance Works has been approved by Department of Roads. This norms may be used as a trial, subsequent corrections will be made after feedback from the Division Offices, and the final norms shall be approved.

1.5 This guidelines prescribes the frequencies with which routine maintenance operations are to be carried out and in some cases the manner in which they are to be performed for given elements and components of structures. They may not be appropriate in all circumstances and may need to be modified to take account of local conditions and the needs of individual structures e.g. by reducing maintenance intervals.

1.6 Maintenance Divisions should identify those items of routine maintenance which are appropriate for each particular structure, and prepare a schedule of operations. This schedule should be either appended to the Maintenance Manual or filed within a Divisional Bridge Data Base.

1.7 These guidelines will cover for routine maintenance of works for the bridges as specified by Nepal Road Standard.

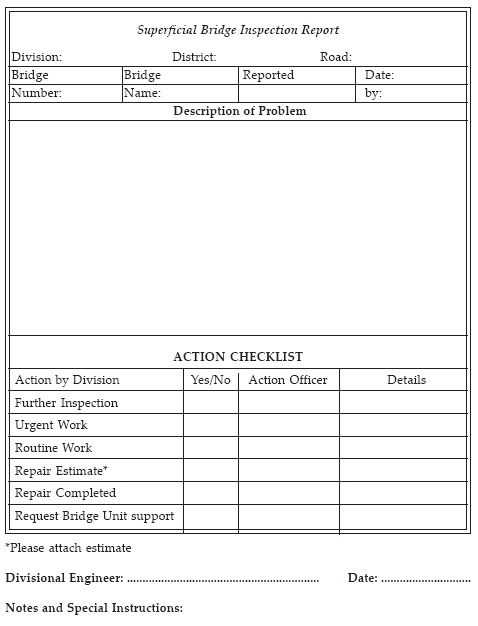

Superficial Inspection Report form

1.8 During the Routine Maintenance activity a Superficial Inspection Report Form shall be completed. Anything noticed of serious nature should be reported immediately. A separate form is used for each structure and is returned to the Divisional Engineer who will take action. The Divisional Engineer will then either instruct the necessary works or send the report to the Bridge Unit for further detailed investigation by the Bridge Unit. Minor Repair Works, if needed can be carried out as mentioned elsewhere in the guidelines. A sample superficial inspection report form is attached as Section 8.

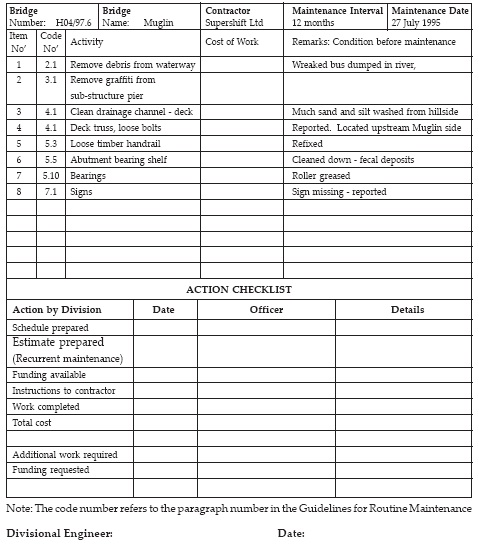

Routine Maintenance Schedule

1.9 A Routine Maintenance Schedule is filed on each bridge every twelve months by the Division. The Routine Maintenance Schedule can be used by the Division as a basis for preparing the Budget application for recurrent maintenance within the Division for the next financial year. A sample Routine Maintenance Schedule is attached as Section 9.

2. ROUTINE MAINTENANCE OPERATIONS : WATERWAY

River Channel, Stream-Bed and Banks

2.1 Requirements for Maintenance

i. Remove accumulation of debris and vegetation, especially tree trunks and branches, especially around and between piers and abutments.

ii. Note new erosion and scour on superficial inspection report forms.

iii. Note deposition of river bed material on superficial inspection report forms.

iv. Note change of river direction on superficial inspection report forms.

v. Note any extraction of sand or gravel within 200 metres upstream or downstream of the structure on the superficial inspection report forms.

vi. Clear any encroachments in the area of the bridge site.

2.2 Maintenance Interval

3 – 4 times a year.

2.3 Time of Maintenance

Before start of the monsoon season. (July). During the dry season after the monsoon season when the rivers are low. (October). After large floods during the monsoon season.

3. ROUTINE MAINTENANCE OPERATIONS: SUB STRUCTURES

Reinforced Concrete, Mass Concrete, Masonry and Timber - Piers and Abutments

3.1 Requirements for Maintenance

i. Remove Graffiti

ii. Remove any vegetation from the structure.

iii. Clear debris including animal and fecal deposits from bearing shelves and bridge surfaces.

iv. Clean drainage channels.

v. Clean out drainage pipes and remove silt and debris. Test on completion

vi. Report damaged or missing gap sealant to movement joints on superficial inspection report form

3.2 Maintenance interval

3 – 4 times a year.

3.3 Time of Maintenance

(Ideally) all drains to be cleared after leaf fall and working properly before the monsoon starts (July). All vegetation to be cleared before the growing season (April). Reinforced Concrete, Mass Concrete and Masonry - Wing-Walls, Retaining Walls. Reinforced Earth Walls and Gabion Walls.

3.4 Requirements for Maintenance

i. Remove Graffiti

ii. Clean out weep pipes and remove silt and debris.

iii. Remove any vegetation from the Structure.

iv. Remove all debris including animal and fecal deposits and clean drainage channels.

v. Clean outlet pipes and test on completion.

vi. Report damaged or missing gap sealant to movement joints on superficial inspection report form

3.5 Maintenance interval

3 – 4 times a year.

3.6 Time of Maintenance

All drains to be cleared after leaf fall and working properly before the monsoon starts(July). All vegetation to be cleared before the growing season (April).

3. ROUTINE MAINTENANCE OPERATIONS: SUB STRUCTURES

Steel, Concrete and Timber Columns and Frames

3.7 Requirements for Maintenance

i. Remove Graffiti

ii. Remove debris, bird droppings, animal and fecal deposits from all surfaces

3.8 Maintenance Interval

3 – 4 times a year.

4. ROUTINE MAINTENANCE OPERATIONS: SUPERSTRUCTURES

Steel , Concrete and Timber Beams, Trusses and Decks, Concrete Slabs

4.1 Requirements for Maintenance

i. Remove Graffiti

ii. Remove any vegetation from the structure.

iii. Clear debris and stones including animal and fecal deposits from bridge deck and surfaces.

iv. Clean drainage channels.

v. Clear drainage outlet pipes to ensure effective operations. Test on completion.

vi. Clear weep pipes and remove silt and debris.

vii. Check all bolts and nuts for tightness, report missing or loose bolts on superficial inspection report forms.

viii. Report cracks, deformation and potholes in bridge deck surfacing on superficial inspection report forms.

ix. Report damaged or missing gap sealant to movement joints on superficial inspection report form

4.2 Maintenance interval

3 – 4 times a year.

4.3 Time of Maintenance

(Ideally) all drains to be cleared after leaf fall and working properly before the monsoon starts (July). All vegetation to be cleared before the growing season (April).

5. ROUTINE MAINTENANCE OPERATIONS: COMPONENTS

Expansion Joints and Bridge Joint Systems

5.1.Requirements for maintenance

i. Clean out stones, debris and vegetation. (For large movement joints with access provision from below this may require low pressure water washing.)

ii. Check condition of joint sealant where applicable. Report damaged or missing gap sealant to movement joints on superficial inspection report form

iii. Clear drainage systems.

iv. Check all bolts and nuts for tightness. Report loose or missing bolts on the superficial inspection report form.

v. Replace gaskets etc. where this is a requirement of the specific maintenance manual.

vi. Report wear, damage and deformation in joint, lack of freedom of movement, jamming of joint due to debris, lack of proper clearance or incorrect vertical or horizontal alignment on superficial inspection report form.

vii. Report cracks in adjacent surfacing and wearing course on superficial inspection report form.

5.2 Maintenance Interval

3 – 4 times a year.

Metal Parapets, Concrete Parapets, Timber Railings and Safety Fences

5.3 Requirements for Maintenance

i. Check all bolts and nuts for tightness. Report loose or missing bolts on the superficial inspection report form.

ii. Clear hollow section drain holes.

iii. Remove graffiti, vegetation and debris.

iv. Report any damage on superficial inspection report form.

5.4 Maintenance Interval

3 – 4 times a year.

5. ROUTINE MAINTENANCE OPERATIONS: COMPONENTS

Bearings

5.5 Requirements for Maintenance - General

i. Remove any vegetation from the bearing shelf and/or bearing plinth.

ii. Clear debris and stones including animal and fecal deposits from bearing shelf and/or bearing plinth.

5.6 Requirements for Maintenance - Elastomeric

i. Remove general debris and dirt.

ii. Report any damage including tearing, bulging, deterioration, flattening, other abnormal deformation, loose bearings and mortar, stress cracks in structure, on superficial inspection report forms.

5.7 Maintenance Intervals

3 – 4 times a year.

5.8 Requirements for maintenance - Sliding

i. Clean to ensure sliding surfaces perform satisfactorily.

ii. Remove general debris and dirt.

iii. Clear and clean contact surfaces where accessible and re-grease/lubricate in accordance with manufacturer’s instructions, in the maintenance manual.

iv. Report damaged, loose bearings, bolts and mortar bedding, stress cracks in structure

v. Report corrosion of bearing surfaces

5.9 Maintenance Intervals

3 – 4 times a year.

5.10 Requirements for Maintenance - Roller

i. Remove general debris and dirt

ii. Clear and clean roller surfaces where accessible and re-grease if necessary. (Identify Manufacturers instructions in maintenance manual).

iii. Report damaged, loose bearings, bolts and mortar bedding, stress cracks in structure

iv. Report corrosion of bearing surfaces

5.10 Maintenance Intervals

3 –4 times a year.

5.11 Requirements for Maintenance - Special Bearings, PTFE etc.

Refer to manufacturers instructions and maintenance manual.

Earthquake Restraints

5.12 Requirements for Maintenance

i. Check all bolts and nuts for tightness. Report loose or missing bolts on the superficial inspection report form.

ii. Check steel sections for deformation.

iii. Check for missing or damaged bearing parts, such as vertical or horizontal elastomeric pads.

iv. Report corrosion of earthquake restraints.

v. Report any damage on superficial inspection report form.

5.13 Maintenance Interval

3– 4 times a year.

6. ROUTINE MAINTENANCE OPERATIONS: PROTECTIVE SYSTEMS

6.1 Requirements for Maintenance

i. Clean surfaces of debris, animal and fecal contamination.

ii. Report damage and/or corrosion, breakdown of protective system on superficial inspection report form.

6.2 Maintenance interval

3 – 4 times a year.

7. ROUTINE MAINTENANCE OPERATIONS: BRIDGE SIGNS

Bridge Signs

7.1 Requirements for Maintenance

i. Clean surfaces of all signs including chevrons.

ii. Remove all notices and advertisements from signs.

iii. Report all damage to signs, including chevrons on superficial inspection report form

7.2 Maintenance Interval

3 – 4 times a year.

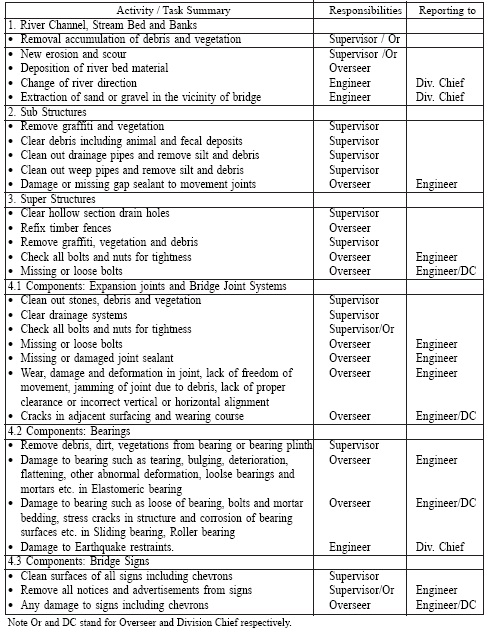

8. Responsibilties and Reporting Authority of Routine Maintenance Activities

9. SUPERFICIAL INSPECTION REPORT FORM (SAMPLE):

10. ROUTINE MAINTENANCE - SCHEDULE

Given below is a completed sample Routine Maintenance Schedule. A schedule is drawn up for each bridge by the Division after referring to the Guidelines for Routine Maintenance. This would then form part of the Divisional Bridge Inventory Record for the Bridge.

Routine Maintenance - Schedule

Division:

11. INTERIM NORMS FOR ROUTINE BRIDGE MAINTENANCE

12. MODALITY OF IMPLEMENTATION OF ROUTINE MAINTENANCE ACTIVITIES

Routine maintenance has been introduced DoR SMD programme III recently in the fiscal year 2061/62. An interim norms has been approved by the Department which will be developed to final norms with the necessary corrections after receiving suggestion from division offices.

The number and total length of bridges vary in each division. The distances between the two bridges vary from few meters to several kilometers. There seem practical difficulties to implement routine bridge maintenance works in the same manner of routine road maintenance works. Thus an effective modality of implementation of routine maintenance works shall be developed. Following modalities are proposed at the starting which may be reviewed and updated.

(1) Form groups of 2 (at least) to 4 labourers as allowed by the approved norms. Assign these group THROUGHOUT the year in cyclic order to various locations of the division so that each bridge is attempted 4 to 5 times a year. This modality is suitable for the divisions having bridges at close distances and having more lengths of bridges.

(2) Total mandays allowed by the norms is calculated. Hire a group of 2 to 4 labourers, for required time, locally and assign the group for the works on the bridges with a workable stretch of road length. Another group is formed for another site accordingly and maintenance works are carried out such that each bridge is attempted 3 to 5 times a year. This modality is suitable for the divisions having bridges at longer distances and having lesser total lengths of bridges.

(3) Divisions may submit any other implementation modalities which are suitable to the respective divisions and discussed with BU/SMD.

(4) The same supervisors from the routine road maintenance works will be used for the supervision works.

Equipment list:

The following equipments are proposed for carrying out the works

1) Safety jackets 2) Gloves 3) Safety helmet 4) Rain coat 5)Bicycle 6) Ladders 7) Other tools such as First aid kit, Axe, Hasiaya, Knife, Hammer, Gainti, Saw, Traffic cones.

The equipment list from part 2: Bridge Inspection Manual shall also be referred. The above equipment are as guidelines, the divisions shall propose other equipment if needed. For the year 2061/62, the divisions should purchase a new set of tools and equipment. SMD has agreed to supplement equipment to those divisions where the assigned budget for the tools and plants are inadequate for the year 2061/62.

As a guide following set of major equipment and services are suggested be provided:

1. One to two bicycles for 2 man-days as per site requirements.

2. Safetywares and raincoat for each man-day labour as per the norms.

3. Ladders and tool sets as following:

up to 1000 m bridge length 1 set

from 1000 m to 5000 m bridge length additional 1 set

from 5000 m above additional 1 set